Rubber-lined pneumatic butterfly valves are suitable for the transportation of liquids and gases (including steam) and other media in various types of industrial pipelines, as well as the use conditions of weakly corrosive fluid media, for two-position switch control or medium flow rate adjustment. The working temperature generally does not exceed 180℃, and the nominal pressure is ≤1.6MPa. It is widely used in food, medicine, chemical industry, petroleum, electric power, textile, papermaking and other places.

Performance characteristics of pneumatic rubber-lined butterfly valve:

1. The use of rubber-lined pin-free ensures complete isolation of the medium and metal, improving the reliability of the product.

2. The sealing surface has good wear resistance (the wear resistance of rubber is seven times that of copper).

3. It can be installed at any position and is easy to maintain.

4. The seals can be replaced, and the sealing performance is reliable and achieves two-way sealing and zero leakage.

5. The rubber material has no toxicity, is antibacterial and anti-mildew, and the product price is one-third of that of stainless steel valves.

Technical parameters of pneumatic rubber-lined butterfly valve:

|

Nominal diameter

|

DN50~DN1200(mm)

|

|

Pressure Level

|

PN0.6、1.0、1.6MPa

|

|

Connection method

|

Clamp type, flange connection

|

|

Drive mode

|

Pneumatic control (air source drive, compressed air)

|

|

proper temperature

|

Various rubbers: -20℃~150℃

|

|

Leakage amount

|

Comply with standards (up to zero leakage)

|

|

Sealed structure

|

Half rubber-lined seal, fully rubber-lined seal

|

|

workplace

|

Water, gas, oil and weakly corrosive fluids (normal temperature and pressure situations)

|

|

control method

|

Switch two-position mode (gas on and off), regulating type (4~20mA analog signal control)

|

|

Standard specifications for pneumatic rubber-lined butterfly valves:

Design and manufacturing standards: GB/T 12238-2008

Structural length standard: GB/T 12221-2005

Connection flange standard: GB/T 9113

Pressure temperature grade: GB/T 12224-2005

Test and inspection standards: GB/T 13927-2008

|

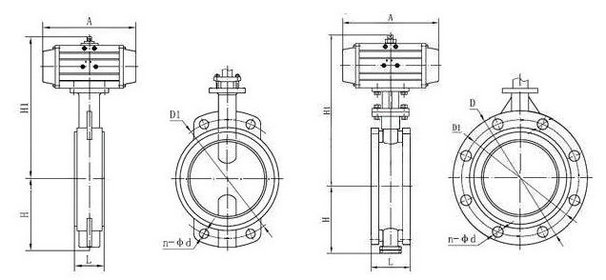

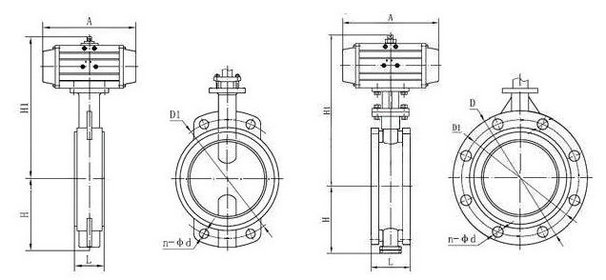

Pneumatic rubber-lined butterfly valve (wafer type) Pneumatic rubber-lined butterfly valve (flange type)

|

Pneumatic rubber lined butterfly valve parts materials:

Valve body: cast iron, ductile iron, carbon steel, stainless steel

Butterfly plate: cast iron, ductile iron, carbon steel, stainless steel fully covered with rubber or fluoroplastic

Valve stem: carbon steel plated with nickel phosphorus, stainless steel

Valve seat seal: natural rubber NR, neoprene CR, nitrile rubber NBR, EPDM, fluorine rubber FKM

Seal ring operating temperature: nitrile rubber X≤80 degrees; wear-resistant rubber X6≤150 degrees; chloroprene rubber ≤120 degrees; fluorine rubber X7≤150 degrees;

Pneumatic rubber-lined butterfly valve performance specifications:

|

Nominal diameter

|

DN(mm)

|

50~1200

|

|

Nominal pressure

|

PN(MPa)

|

0.6

|

1.0

|

1.6

|

|

test pressure

|

Strength test

|

0.9

|

1.5

|

2.4

|

|

Sealing test

|

0.66

|

1.1

|

1.76

|

|

Air seal test

|

0.6

|

0.6

|

0.6

|

|

Action form

|

Double acting (gas on and off), single acting (normally closed, normally open)

|

|

Optional accessories

|

Positioner, solenoid valve, air filter pressure reducer, position retaining valve, travel switch, valve position transmitter, handwheel mechanism, etc.

|