The difference between pneumatic soft seal butterfly valve and pneumatic hard seal butterfly valve :

1. Soft seal butterfly valves are mostly centerline type, while hard seal butterfly valves are mostly single eccentric, double eccentric or triple eccentric butterfly valve structures.

2. Soft seal is used in normal temperature environment. Hard seals can be used in low temperature, normal temperature, high temperature and other environments.

3. The soft seal is used for low pressure - normal pressure, and the hard seal can also be used for medium and high pressure.

4. Soft seal and triple eccentric hard seal butterfly valves have better sealing performance. Triple eccentric butterfly valves can maintain good sealing in high pressure and high temperature environments.

5. The advantage of soft-sealing butterfly valve is good sealing performance, but the disadvantage is that it is easy to age, wear and have a short service life .

6. Hard-sealed butterfly valves have a long service life, but their sealing performance is relatively worse than soft seals.

|

Advantages of pneumatic soft seal butterfly valve:

1. The structure is simple, the flow resistance coefficient is small, the flow characteristics tend to be linear, and no debris will be retained.

2. The connection between the butterfly plate and the valve stem adopts a pinless structure, which overcomes possible internal leakage points.

3. It is divided into pneumatic wafer-type soft-sealing butterfly valve and pneumatic flange soft-sealing butterfly valve to meet different pipelines.

4. The seals can be replaced, and the sealing performance is reliable and achieves two-way sealing and zero leakage.

5. The sealing material is resistant to aging and corrosion and has a long service life.

|

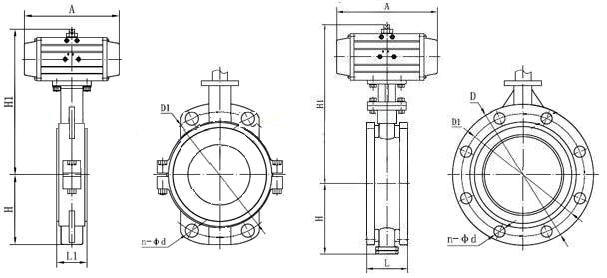

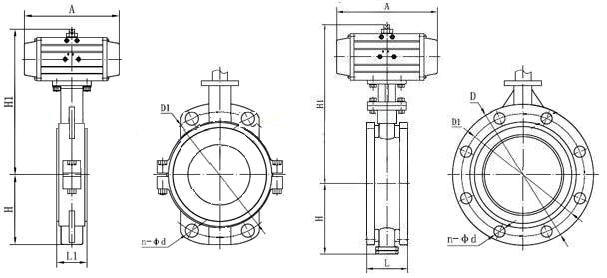

Pneumatic wafer type soft sealing butterfly valve structure Pneumatic flange soft sealing butterfly valve structure

|

Pneumatic soft seal butterfly valve sealing material:

|

Material variety

|

Neoprene

|

Nitrile rubber

|

Ethylene propylene rubber

|

PTFE

|

Silicone Rubber

|

fluororubber

|

|

code name

|

×or0rJ

|

XA or JA

|

XBororJB

|

xC, JC or 0rF

|

XD or orJD

|

× E or JE

|

|

Resistant to higher temperatures

|

82℃

|

93℃

|

150℃

|

232℃

|

250℃

|

204℃

|

|

Resistant to lower temperatures

|

-40℃

|

-40℃

|

-40℃

|

-268℃

|

-70℃

|

-23℃

|

|

Applicable working temperature

|

≤65℃

|

≤80℃

|

≤120℃

|

≤200℃

|

≤200℃

|

≤180℃

|

Pneumatic soft seal butterfly valve parameter description:

|

Nominal diameter

|

DN50~DN1200(mm)

|

|

Pressure Level

|

PN1.0、1.6、2.5MPa

|

|

Connection method

|

Clamp or flange connection

|

|

Spool form

|

Disc type

|

|

Drive mode

|

Air source driven, compressed air 5~7bar (can be equipped with handwheel)

|

|

Action range

|

0~90°

|

|

Sealing material

|

Various rubbers, polytetrafluoroethylene

|

|

workplace

|

Various corrosive media, etc. (normal temperature and pressure, low temperature and low pressure occasions)

|

|

Accessory options

|

Positioner, solenoid valve, air filter pressure reducer, position retaining valve, travel switch, valve position transmitter, handwheel mechanism, etc.

|

|

control method

|

Two-position switch control, air-open, air-close, spring return, intelligent adjustment type (4~20mA analog signal)

|