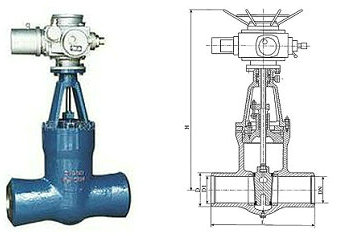

Electric Welding Gate Valve

Keywords: metering pump accessories

Classification:

Electric gate valve

- DESCRIPTION

-

Advantages of electric welded gate valve:

1. The shell adopts precision casting technology, with smooth appearance and uniform structure, meeting the requirements of high, medium and low pressure.

2. The welded electric gate valve is designed and manufactured in accordance with JB/T3595 and other standards and can be used with domestic equipment.

3. The middle cavity of the valve adopts a pressure self-tightening sealing structure with good sealing performance. Both ends of the branch pipe are welded structures.

4. The valve stem has been tempered and surface nitrided, and has good corrosion resistance and scratch resistance.

5. High-pressure water strength, high-pressure gas strength, non-destructive testing and other multi-channel testing to comprehensively control the quality of steel castings.

Electric welding gate valve structure diagramProduct parameters

Technical parameters of electric welded gate valve:

Installation and maintenance of electric welded gate valve:

1. When welding the gate valve to the pipeline, the valve should be opened, and the neck should be properly protected with moisture to minimize high-temperature heat conduction to prevent damage to the sealing packing.

2. It is strictly forbidden to use the booster rod when closing the valve. When the gate is closed to the top, the handwheel should be rotated 1/2 turn to make the gate in a floating state.

3. During the use of the gate valve, a certain amount of grease should be injected regularly into the bonnet grease joint.

4. If the valve leaks due to wearing parts during use, it should be replaced in time.

5. During the maintenance process of the valve, the inner cavity should be cleaned, and each transmission part should be greased during assembly.

6. During the storage and out-of-use period of the valve, the gate should be kept in the closed position. For long-term storage, it should be placed in a ventilated and dry place, and should be inspected and maintained regularly.