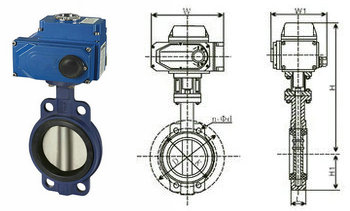

Electric Center Line Butterfly Valve

Keywords: metering pump accessories

Classification:

Electric butterfly valve

- DESCRIPTION

-

Structural features of electric center line butterfly valve:

1. The valve can be designed with flange connection, clamp connection and single clamp connection.

2. The same pole can be designed as a through pole, with a pin and a hexagonal head connection structure of two sections of pole.

3. Since the sealing surface of the valve seat and the backrest are integrated, the deformation of the valve seat is reduced.

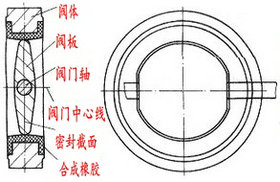

4. The rotation center of the butterfly plate (that is, the center of the valve stem) is located on the center line of the valve body and the sealing surface section of the butterfly plate.

5. The valve seat is made of synthetic rubber. When closing, the outer circular sealing surface of the butterfly plate squeezes the synthetic rubber valve seat, causing the valve seat to elastically deform and form elastic force as the sealing specific pressure to ensure the sealing of the butterfly valve.

Product parameters

Technical parameters of electric centerline butterfly valve: