Electric Fluorine Lined Butterfly Valve

Keywords: metering pump accessories

Classification:

Electric butterfly valve

- DESCRIPTION

-

Application of electric fluorine lined butterfly valve:

The electric fluorine-lined butterfly valve is a thick layer of fluoroplastic polymer material that lines the flow-passing parts (disc, inner wall of the valve body) that are in contact with the medium, so it is also called an electric plastic-lined butterfly valve and is suitable for various applications. The transportation of liquids and gases (including steam) in different industrial pipelines, especially the use of severely corrosive, erosive, and abrasive media, such as sulfuric acid, hydrofluoric acid, phosphoric acid, chlorine, strong alkali, aqua regia, etc. Corrosive media, but not suitable for process media with particles and high temperatures.

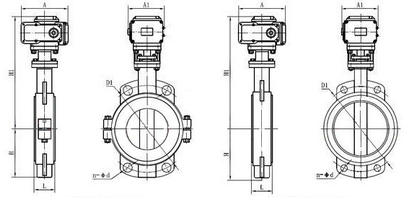

Electric wafer-lined fluorine-lined butterfly valve Electric flange-lined fluorine-lined butterfly valveProduct parameters

Technical parameters of electric fluorine lined butterfly valve:

Applicable temperature of electric fluorine-lined butterfly valve (℃):

1. Polyperfluoroethylene FEP (F46): -85~150

2. Tetrafluoroethylene-ethylene ETFE (F40): -80--220

3. Soluble tetrafluoro PFA (FA ): -70~200

4. Polytetrafluoroethylene PTFE (F4): -200~180

5. Polyvinylidene fluoride PVDF (F2): -70~100

6. Modified polyethylene FRPE (PO): -58 ~80Different materials are suitable for different temperatures and different media

Electric fluorine lined butterfly valve (fully lined with fluorine) Electric fluorine lined butterfly valve (semi lined with fluorine)Performance characteristics of electric fluorine lined butterfly valve:

1. The valve body is available in stainless steel and other materials, and is light in weight and has fast electric switching speed;

2. The sealing material of the electric anti-corrosion butterfly valve has a long service life and is resistant to aging, corrosion and erosion;

3. It can be installed at any position and is easy to maintain. The flange clamp hole connection is applicable to a variety of standards;

4. The electric corrosion-resistant butterfly valve seals can be replaced, the sealing performance is reliable, and it can achieve two-way sealing and zero leakage.

5. The electric anti-corrosion butterfly valve is suitable for chemical media. The upper and middle holes on the valve plate adopt a spherical friction surface design, with smaller torque force and excellent sealing performance.

Performance specifications of electric fluorine lined butterfly valve: